Paper Blow is one of our environmentally friendly 100ml paper airless packaging solutions that meets sustainability standards. According to the company’s environmental philosophy: supplement, reuse, reduce, and recycle.

Exclusively available from Korean Manufacturer, with overlapping and outer bottles made from recycled PCR cardboard. They are installed around a tubular PE bag that is connected to a 0.50cc airless pump with an annular neck for easy filling. Use surface friction to blow them into a cardboard bottle to achieve a super tight fit. The pump system is the same as the airless tube-when the formula is used up, the PE bag will fold on its own to prevent air from re-entering.

The PCR outer sheath means that no secondary packaging is required, thereby reducing the overall material usage.

Paper Blow is refillable and offers excellent decoration options for stunning results. Offset printing can be done on thin paper (up to eight colors), and it can be laminated before being pasted on the outer bottle and bottle cap.

What types of Paper Airless Packaging Technology Are Available?

There are three popular airless technology systems:

1. Bag in Bottle (plastic bottles or jars)

2. Piston System (plastic bottles)

3. Bag on Valve (aluminum cans or plastic bottles)

Benefits:

Complete product evacuation is another important driving factor. Consumers spend a lot of money on products (especially cosmetics), hoping to ensure that they can withdraw all products. They hope to provide value for these high-priced products and use the last drop.

Ergonomics and convenience are the keys. 360-degree multi-position dispensing, the product can be dispensed in any direction, can be used upright or upside down, zero drive interruption. The 360-degree dispensing capability—especially fine mist and emulsion dispensing—makes it quick and convenient to use.

Consumers also prefer products that meet their safety standards. The non-pressurized tamper-proof dispensing system provides a safe, non-contaminant, and unaltered product.

High-performance single-material airless pump

Although airless pumps are usually made of 9 or 10 different materials, including the metal used for the springs, We have now the first airless pump prototype made only of PE and PP in 2013.

However, the Korean manufacturer had to face many challenges before the pump could reach the same level as standard airless pumps in terms of dosage, high-viscosity formulation pumping, and leakage performance. After years of improvement, our partner’s engineers achieved in 2020 to make it as perfect as a standard pump. They went a step further and applied the same technology to Presto Jar, which is a completely different type of packaging suitable for higher viscosity formulations.

The 2cc / 3cc pump provides the strongest and most efficient pumping performance and is as successful as the multifunctional 0.20cc pump.

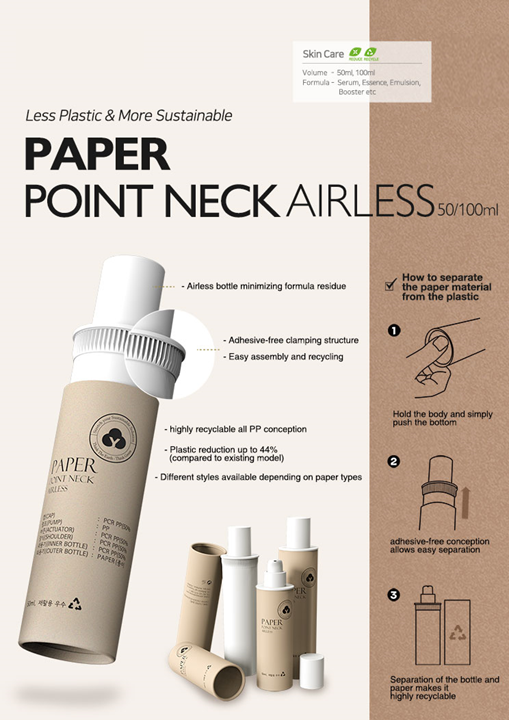

Paper Airless Packaging simples series:

Alternatively, the top cap and outer bottle can be produced from recycled PCR PET, and the filling cap and inner bottle can be produced from PCR PP. “Of course, its airless pump is based on our best airless technology, which can perfectly protect formulas, even organic cosmetics, and other preservative-free formulas,” Joong-hyun Ki concluded.